Precision Water Jet Cutting

At Tutto Ferro, we offer industry-leading water jet cutting services using our OMAX Water Jet. This high-powered cutting system delivers exceptional precision and versatility, making it ideal for both industrial and aesthetic applications. Whether you need one-off prototypes or full production runs, our expert team ensures top-quality results with unbeatable turnaround times. Plus, with a stock of common materials on hand and local pickup and delivery, we make the process seamless from start to finish.

Why Choose Water Jet Cutting?

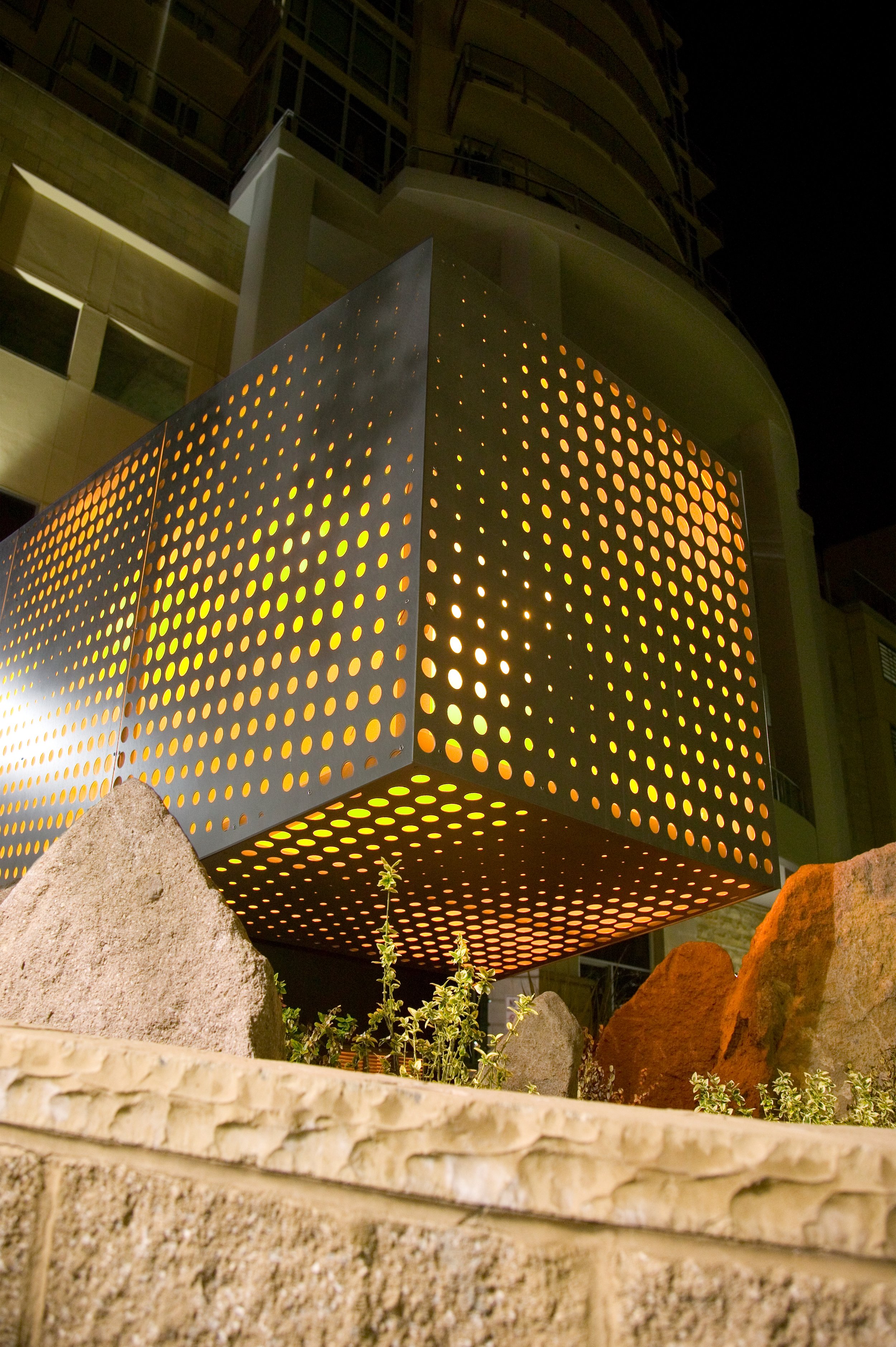

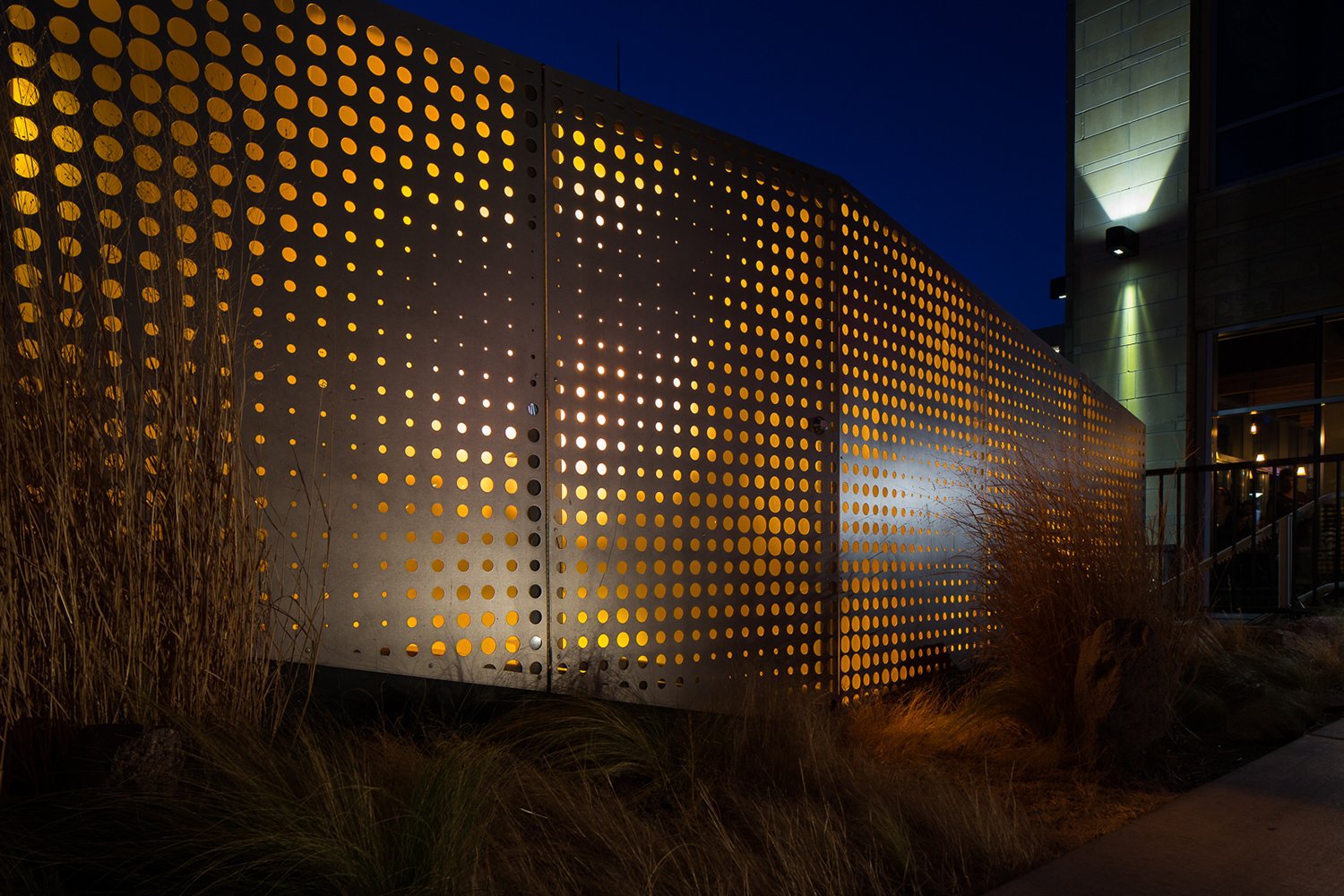

Water jet cutting is the go-to method for achieving precision, high-quality cuts on a wide variety of materials. It offers a non-thermal cutting process, which means no material distortion due to heat—perfect for projects that demand both intricate detail and structural integrity.

Our OMAX Water Jet system is capable of cutting through almost any material, including steel, titanium, concrete, glass, and more—with unmatched accuracy.

Capabilities

Large Cutting Envelope – Handles materials up to 60” x 144”, with a primary cutting area of 55” x 100”.

Unmatched Thickness Capacity – Cuts materials up to 7.5” thick, including metals, composites, and stone.

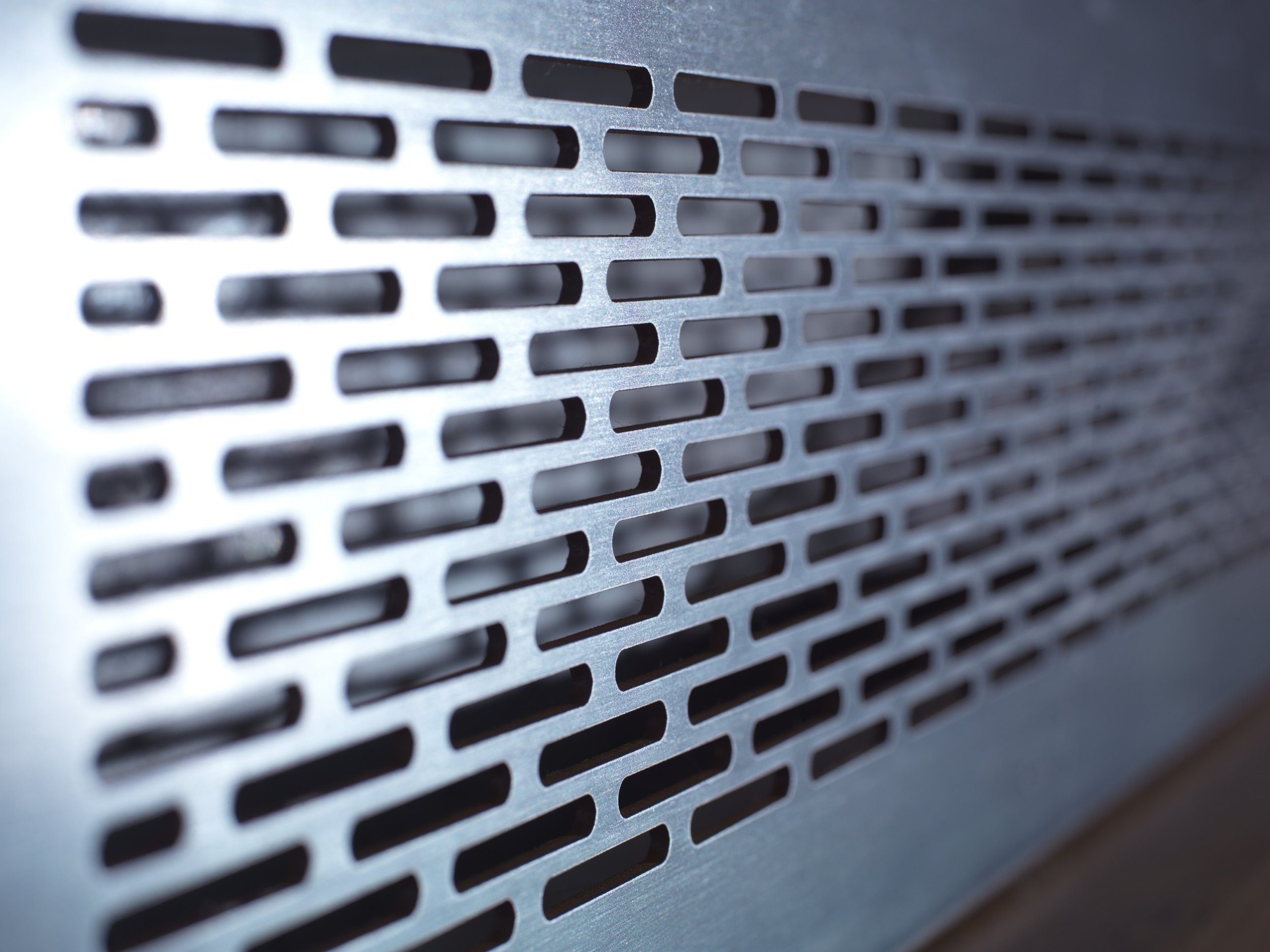

Ultra-Precise Cutting Tolerances – Holds ± .005” at the highest quality, with positioning accuracy of ± .001”.

Fine Kerf Width – Produces cuts as narrow as .030” for detailed, intricate work.

Extreme Cutting Force – Operates at 60,000 psi, enabling smooth, precise cuts on nearly any material.

Versatile Material Compatibility

Our water jet system can cut virtually any material, including:

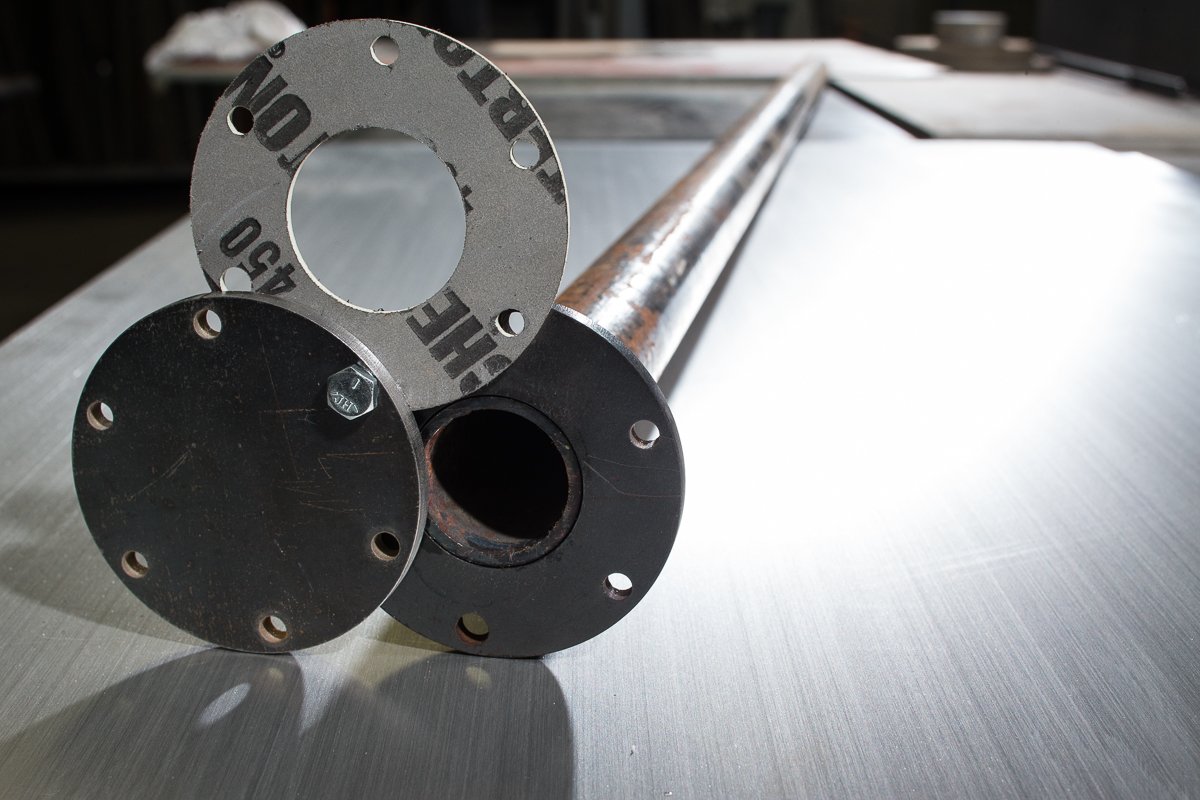

Metals: Steel (up to 7.5”), titanium, aluminum, brass, copper, and armor plate

Non-Metals: Glass, wood, composites, plastics, rubber, and ceramics

Specialty Materials: Concrete, stone, and even delicate materials like carbon fiber