high-definition plasma cutter

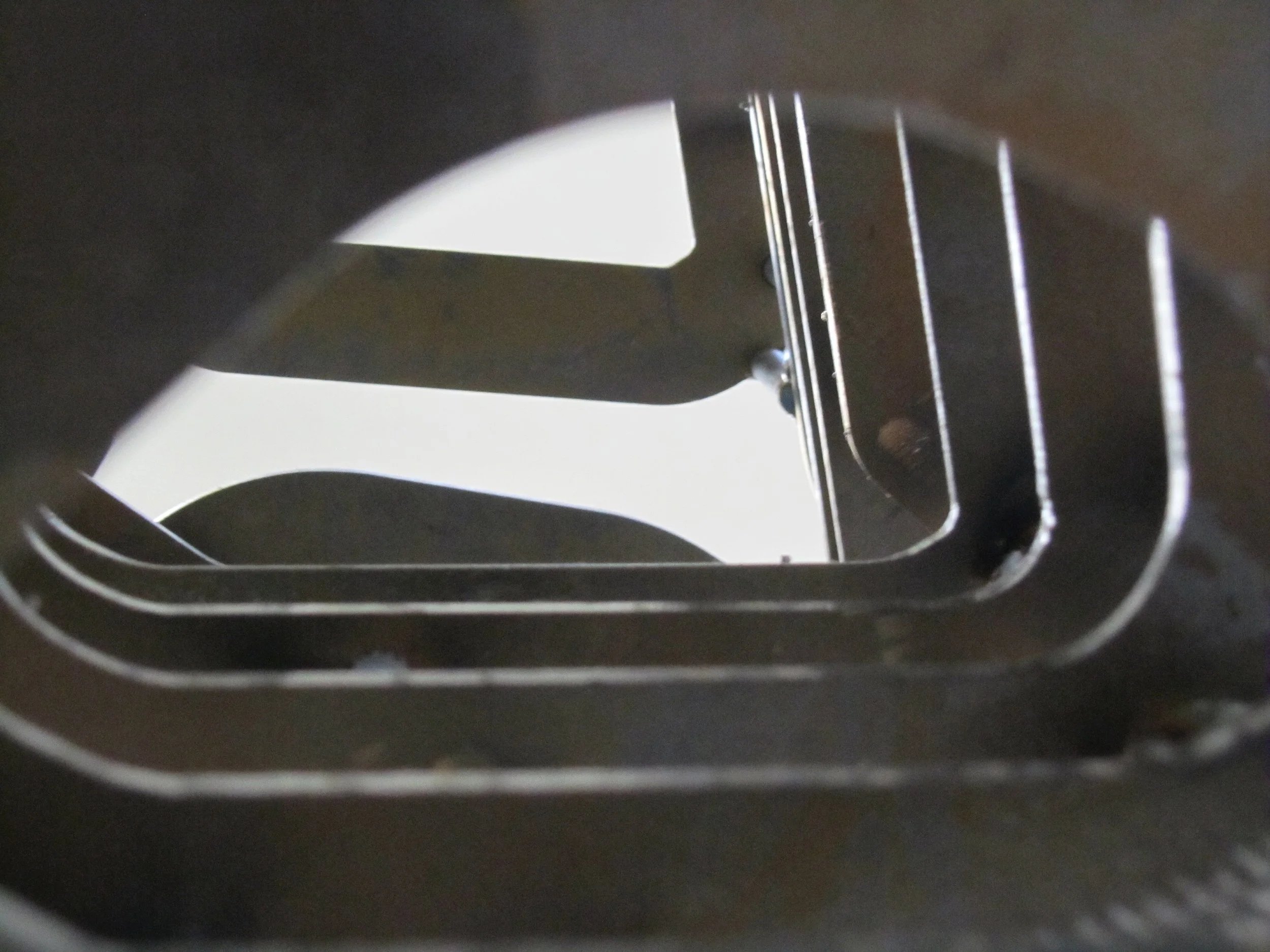

At Tutto Ferro, we bring speed, precision, and affordability to metal fabrication with our Torchmate Plasma Table. Whether you need durable industrial components, custom signage, or intricate metalwork, our plasma cutting services deliver clean, accurate cuts with fast turnaround times. For projects where a water jet’s ultra-fine finish isn’t necessary, plasma cutting offers a cost-effective alternative without sacrificing quality.

Why Choose Plasma Cutting?

Plasma cutting is an ideal option for fabricators, manufacturers, and custom projects requiring durable, accurate cuts without excessive processing time. Whether you need industrial components, signage, or custom metalwork, our plasma table ensures reliable results at a competitive price.

Plasma Cutting Capabilities

Large Cutting Envelope – Up to 60” x 120”, accommodating a wide range of project sizes.

Versatile Material Cutting – Handles mild steel up to 5/8” thick and stainless steel up to ¼” thick.

Precision Part Marking & Engraving – Add part numbers, guides, or decorative elements directly onto your pieces.

Cost-Effective & Efficient

Plasma cutting is an excellent choice when speed and affordability matter. Unlike water jet cutting, which provides a refined edge finish, plasma cutting efficiently handles projects where a clean but functional cut is required. This makes it perfect for structural components, brackets, signs, and industrial applications.